1. EARLY STAGES

The basic transformer principle and its applications in the electrical equipment domain were systematically discovered in the nineteenth century by a series of creative engineers and inventors, many of whose names are, to this day, associated with some of our most common tools and processes.

From the initial discovery of electromagnetic induction to the development of the first spark inductors, firstly in open-coil form and ultimately as closes coils, these pioneers proposed many alternating current applications that would become such innovations as revolutionary electric public lighting system, thus beginning the practical transformer technology for consumers in the domestic and industrial arenas. They have bequeathed this fine heritage to all.

1.1 The process of Discovery of Transformer Principles

In 1831, Michael Faraday demonstrated the principle of electromagnetic induction, creating a voltage pulse across the secondary terminals of his experimental apparatus by interrupting a direct current flowing in the primary coil. Faraday understood that a current variaton in one coil would generate voltage in another coil. Faraday, as far as we know, did not foresee practical uses of his discovery because, up to that time, AC had been considered unsuitable for industrial purposes and only DC applications were being used for electrochemistry and electroplating.

1.2 Spark Inductor

In 1832, Joseph Henry discovered the concept of self-inductance, and that when interrupting current,

the rapid flux change induced a very hight coil voltage.

In 1836, Nicolas Callan increased the voltage that was generated by using a two-coil converter. when an intermittent current circulated by a battery through a “primary” coil of a few turns, he found that a high voltage appeared at the terminals of the “secondary” coil which comprised a large number of turns. The core used in this experiment was made of a ductile iron bar and was not closed.

In 1838, Charles J Page in America and, in 1842, Antoine Masson in France, were able to generate several kilo volts using similar devices. These were the forth generation of spark inductors.

In 1853, Heinrich Danel Ruhmkorff increased the length of the spark first to 200 mm then to 450 mm, by improving both the vibrator device and the coil insulation.

The spark inductor was, in fact, a high voltage transformer; but, oddly enough at this early stage, it was considered to be a DC device and it contributed more to transformer production technology development that to its theoretical aspects.

1.3 Initial Application of Alternating Current

In the 1850’s, an electrical application finally made it to the forefront in the form of electric lighting using carbon arc lamps.

In 1848, Leon Foucault constructed an automatic electromagnetic regulator. Initially, carbon arc lamps were supplied using a DC generator, but it became quickly apparent that AC generators, which did not have a commutator and were thus cheaper to manufacture, were also suitable for powering arc lamps – hence the birth of the practical application of alternating current.

In the 1870, Pavel Jablochkoff improved the flame-arch lamp using two parallel carbon rods. The use of “Jablochkoff candles” unables wider use of electrial lighting and it made it clear that one generator could actually feed several lamps. When connected in series, a supply of 1000 to 1500 Volts could operate 20 to 30 lamps over several kilometers. The problem was that all lamps had to have identical power and, when one lamp went out, all lampis in the line would be switched off.

In 1877, Jablochkoff realized that instead of a direct connection to the series link, the lamps could be supplied through a two-coil induction device.

1.4 The Secondary Generator

In 1882, Lucien Gaulard from France and the Englishman, John Dixon Gibbs, patented a distributing power system that used alternating current with two-coil induction devices linked by an open iron core.

In 1884 devices, now knows as secondary generators, were used in the first alternating current distribution system to light a twelve kilometer section of the London Underground. Meanwhile, in Italy, all the stations of the Torino-Lanzo railway line where equipped with electric lighting, the most distant lamp being situated 40 km away from the 2000 Volt generator operating at 133 Hz frequency.

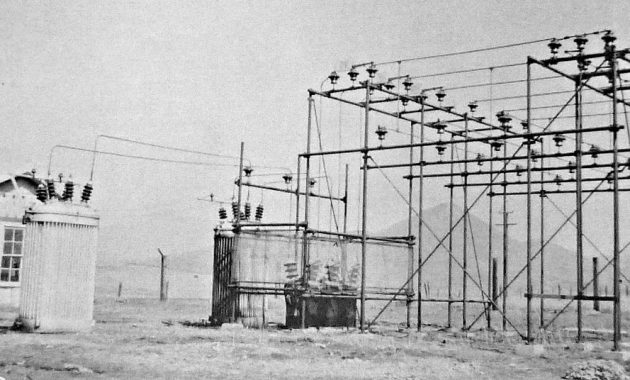

Figure below shows a secondary generator that was built in 1884. Even at this time, the iron core was still open.

In the model shown in figure below the primary winding has 455 discs, the same as on the secondary winding.

By the mid-1880s, the main faults of this device were becoming evident; high reluctance of the iron-air magnetic circuit, a small iron core sectional area, the weak inter-turn insulation that did not permit sufficiently high operating voltages, and the low ratio between the primary and secondary coils.

In the years following the experimental schemes in London and Turin, Gaulard became convinced of the usefulness of using a closed iron core. He built a secondary generator similar to the model shown in Figure below consisting of two generators (as in the previous generation) side-by-side but this time with a single core created by connecting the top and bottom ends of the two previous linear cors.

With this arrangement, it was possible to build generators with a power of 1 kW or more. Despite its imperfections, the secondary generator can be considered as the forerunner of the transformer.

1.5 Transformer Development

In 1885, George Westinghouse foresaw the potential applications of Gaulard and Gibbs’ secondary generators. His development was not new, but his design was the first that could handle high power and that promised to be cheap to manufacture. He imported several apparatus and began experimenting with AC networks. William Stanley, a Westinghouse engineer, was in charge of improving the secondary generator and building the first commercial device.

The first commercial application of the “induction coil” was in 1886, providing lighting for offices and shops of the town of Great Barrington, Massachusetts.

In the meantime, Hungarian engineers Karoly Zipernowsky, Otto Blathy and Miska Deri, from the Ganz Company in Budapest, created a closed core apparatus based upon Gaulard-Gibbs’s work.

The main improvements of the “ZBD” system were:

A high voltage ratio between high voltage (1400 to 2000 V) and lowe voltage (about 100 V). The primaries were connected in parallel to the supply line, rather than in series.

A closed iron core without an air gap at the joint giving a low voltage drop and low loss.

The patent application of this appratus was the first to use the word “transformer” and hence the transformer that we know today was born.

In 1889, the Russian engineer Mikhail Dolivo-Dobrovolski developed the first three-phase transformer.

Thus, the principles of the transformer were established and have remained unchanged up to the present time, though their efficiency and capacities have gone further than any of the early innovators ever would have expected.

The invention of the transformer-connected power system marked a new era in the history of electrical engineering. However, we owe much to Gaulard and Gibbs for their groundberaking invention, which is considered to be the first important step towards the invention of the transformer.

2. TRANSFORMER MILESTONES

As early as the late nineteenth century, the transformer had become an essential piece of electrical equipment for the effective transmission and distribution of energy in the form of efficient electric power.

Transformers change the electric power generated at low voltage into electric power at a higher voltage for transmission, before bringing it back to a lower voltage level appropriate to the end user’s application. As is the case with constant power, the voltage and current vary inversely with one another: so by increasing the voltage level, the current is decreased by the same proportion. This permits reduced conductor section in the transmission lines and in the related infrastructure.

Transformer production lines were started in Hungary in 1889, the during the early 1890’s, in western countries – notably in Europe. In 1893, CFTH (Compagnie Francaise pour l’exploitation des brevets Thomson Houston) commenced production in Paris in cooperation with what would become General Electric Corporation in the USA.

During the industrialization period at the beginning of the 20 th century, transformer manufacturers were, in the main, serving local utilities and working with them in close partnerships. They served the power transformation needs of limited size power plants, industrial mills, local industrial end users, and later on lighting for remote consumers, domestic devices or electromotion. Transformer rated power remained limited to a few thousands of kVA and voltage levels at a few kV.

Stage by stage, the growing needs of electricity end users for power from ever-more remote power generation sites drove the attainment of higher power production capacities and more efficient and competitive transmission solutions. Power station capacities increased, and so did transmission line lengths. To optimize the overall transmission costs, the number of transmission lines in parallel had to be kept to a minimum, and voltage levels were therefore increased to limit nominal current, conductor cross sections, and associated transmission losses (proportional to the second power of current for same conductor section) for the same level of transported power.

In the early part of the 20th century, there was an astounding (at least, it was at that time) voltage leap to 220 kV. However, the demand for power was so great that, a new standard 400 kV voltage level was achieved by the European networks by the middle of the 20 th century. The drive did not halt there and, by the 1960s, the first 800 kV networks were being developed in countries whre generation sites were significantly remote from their major consumption areas (USA, Canada, Venezuela…)).

This evolution was made possible by major improvements in transformer technology, design and manufacturing processes, insulating materials, copper conductors, and magnetic steel. In just over one century of existence, transformer dimensions have considerably decreased whilst performances, power rating and voltage levels have constantly advanced.